In the beating heart of Aprilia, an all-time Italian MotoGP excellence motor house, there’s a strong Team connotation aimed at innovation. Research, technical quality, and, last but not least, sustainability involve the entire company from R&D to pilots.

In this spirit, the Technical partnership between Sharebot and Aprilia was created, where the Sharebot team provided its printers and consultancy for 3D technology. The expert design team of the motorcycle company immediately applied itself with enthusiasm to the new experiments and we are only at the beginning. Below we will show you what has been achieved to date, while new solutions are always being developed.

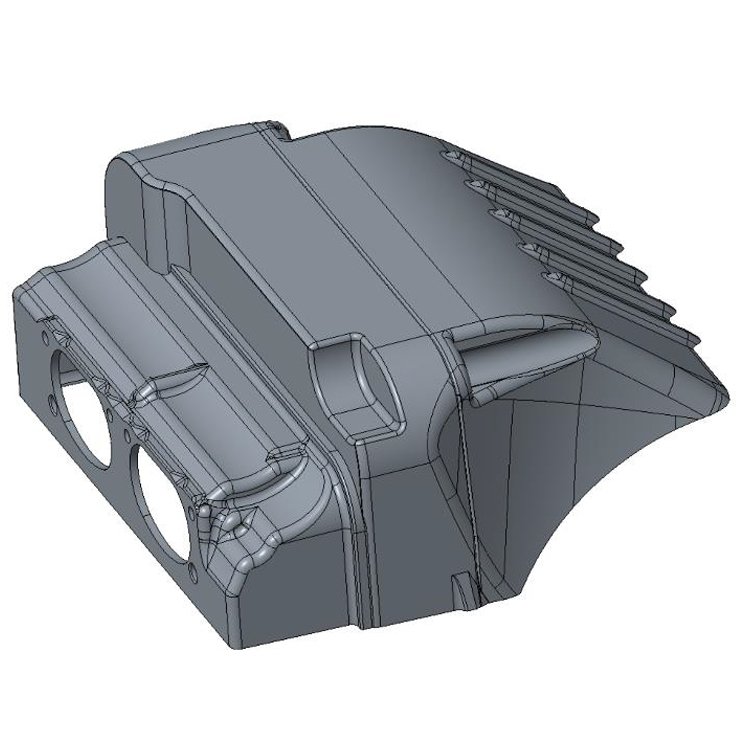

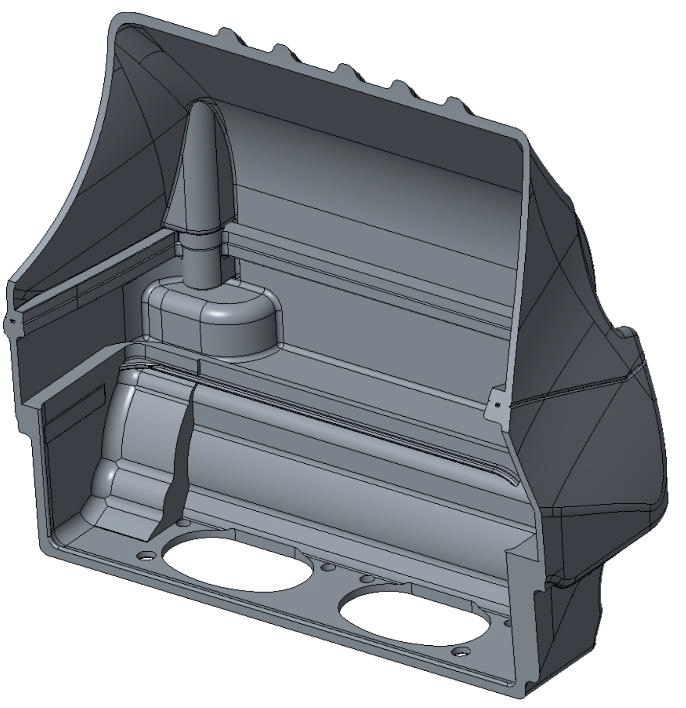

Tank Trimming Template

The first printed model is a template that allows to precisely trim the tank that describes a section of the airbox, created to evaluate its dimensions. This made it possible to verify and validate changes to the tank, without having to create a dedicated one from scratch.

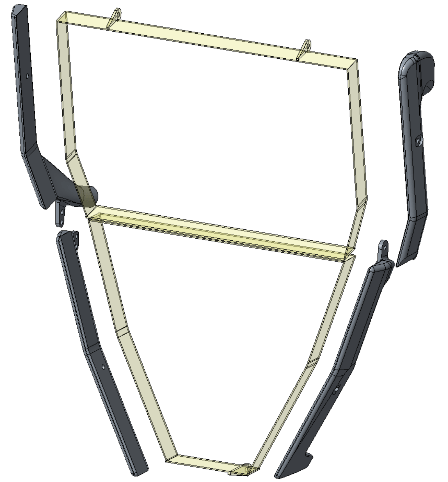

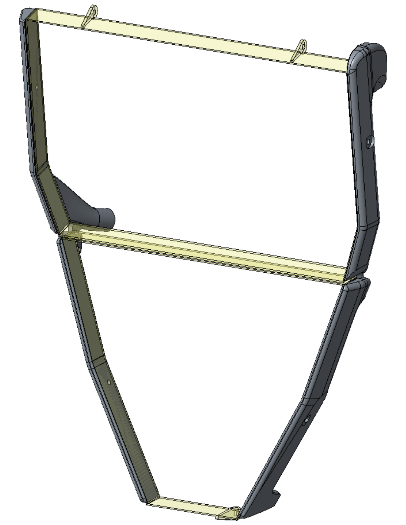

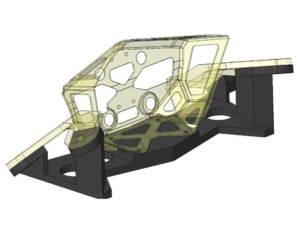

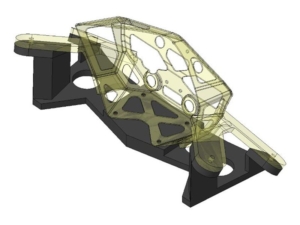

Radiator Trays

The radiator trays were produced to be used and tested in the wind tunnel. This made it possible to save on the production of a complete radiator and to make the coupling with different fairings under development more versatile.

Template for Instrumentation Support

Subsequently, a template was created for the support bracket of the various instruments, in other words the bonding mask for the various supports for the front fairing currently under study.

Push the Limits of Design

Sharebot 3D printers have allowed Aprilia to accelerate creative and production processes, from design to production and testing. Thanks to this technology, you can iterate faster and get finished designs in a very straightforward workflow. 3D printing has also made it possible to overcome the design limitations of some manufacturing technologies used. Thanks to the versatility offered by the Sharebot QXXL, the Aprilia team is now able to manufacture prototypes made with different materials depending on the final use of the piece.

This collaboration is just one of the countless and surprising customizable uses that 3D printing technology offers the world of companies to revolutionize their production processes.

Sharebot is a young and innovative company, with 4 different 3D printing technologies, the last of which is the metal 3d printing, with an R&D that is always updated and operational on the innovations that these modern technologies can offer. It boasts over 3,500 printers around the world including 160 in universities. It ranks among the first places in Europe and the only one on the continent with 4 3D printing technologies: filament, resin, thermoplastic and metal powders.