Snowwhite2: Available powder distributors

Flexibility and Innovation in SLS Printing

The Sharebot SnowWhite2 is a high-performance yet affordable SLS (Selective Laser Sintering) 3D printer designed to meet the needs of universities, research laboratories, and R&D centers focused on experimenting with and developing new polymers and composite materials. Thanks to its open-parameter system, fast setup, and the ability to start testing with just 300g of powder, it offers unparalleled flexibility for scientific research. Additionally, SnowWhite2 is fully customizable, allowing users to adapt hardware and software configurations to optimize performance with specialized materials and processes.

Powder Distribution System: Maximum Adaptability

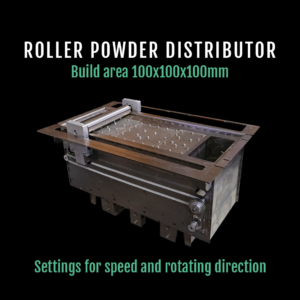

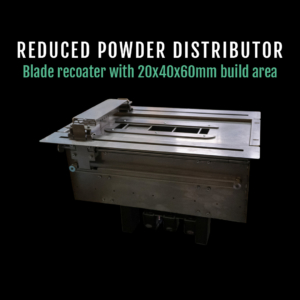

One of SnowWhite2’s most innovative features is the ability to change the powder distribution system, a crucial factor for optimizing printing processes and expanding research possibilities. Depending on research and development needs, users can choose from several interchangeable distributors:

- 10x10x10 cm with a blade recoater

- 10x10x10 cm with a controllable roller

- 2x4x6 cm with a blade recoater

This variety of distributors enables users to replicate the functionality of industrial machines, making it easier to validate processes on a small scale before transitioning to large-scale production. Additionally, it allows for testing powders produced in the lab or working with high-cost materials, reducing waste and optimizing resource consumption.

Advantages of Interchangeable Distributors

The SnowWhite2 powder distributors offer several significant advantages:

- Easy to replace and clean, allowing for quick transitions between tests.

- Independent loading cylinder control, improving precision in powder distribution.

- Compatibility with machines of the same series, enabling research expansion without requiring a new printer.

Potential Applications

Beyond traditional applications in research and development laboratories, SnowWhite2’s interchangeable distribution system can be particularly useful in the following fields:

- Aerospace industry: testing advanced powders for lightweight, high-performance components.

- Biomedical sector: developing customized materials for implants and prosthetics.

- Academic institutions: advanced training on SLS printing technologies and material testing at reduced costs.

Full Customization for Research and Development

Since the SnowWhite2 is entirely designed and developed by Sharebot, it offers a unique advantage: users can request modifications or integrations to enhance the system with new functionalities. Whether for specific research needs, improved material compatibility, or the development of proprietary processes, Sharebot can collaborate with users to tailor the machine’s hardware and software for optimized performance. This adaptability makes SnowWhite2 not just a printer, but a dynamic tool for pushing the boundaries of SLS 3D printing technology.

Thanks to this flexibility, the Sharebot SnowWhite2 stands out as an innovative and adaptable solution, perfect for those looking to explore the potential of SLS 3D printing with maximum configuration and experimentation freedom.