Sharebot metalONE

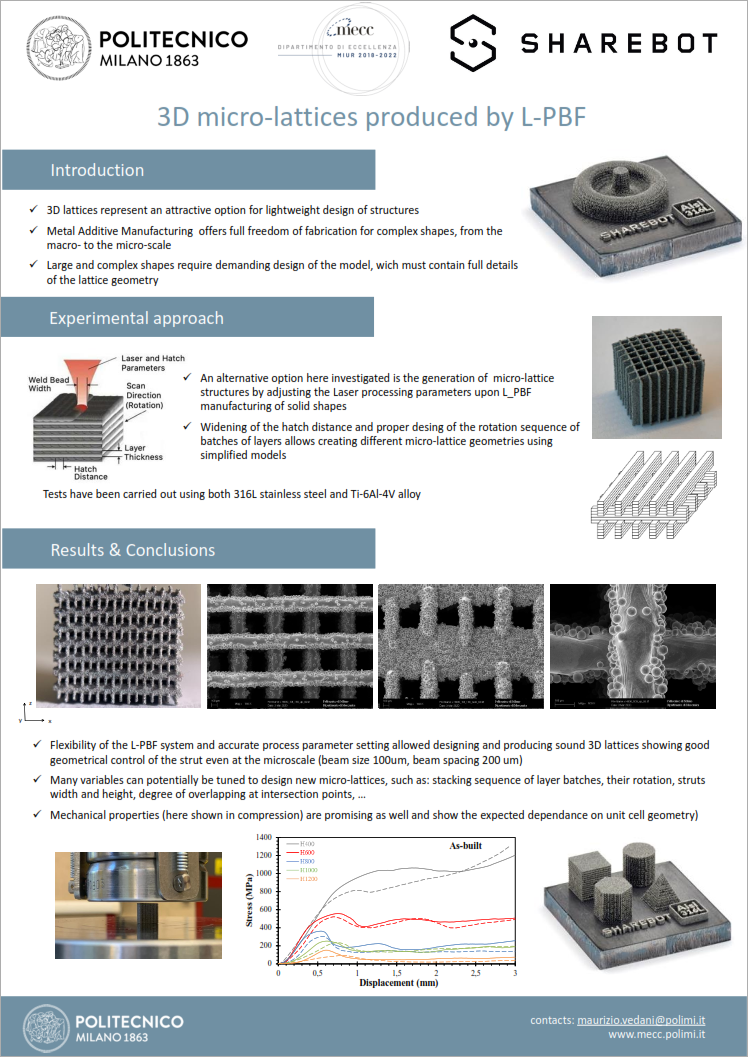

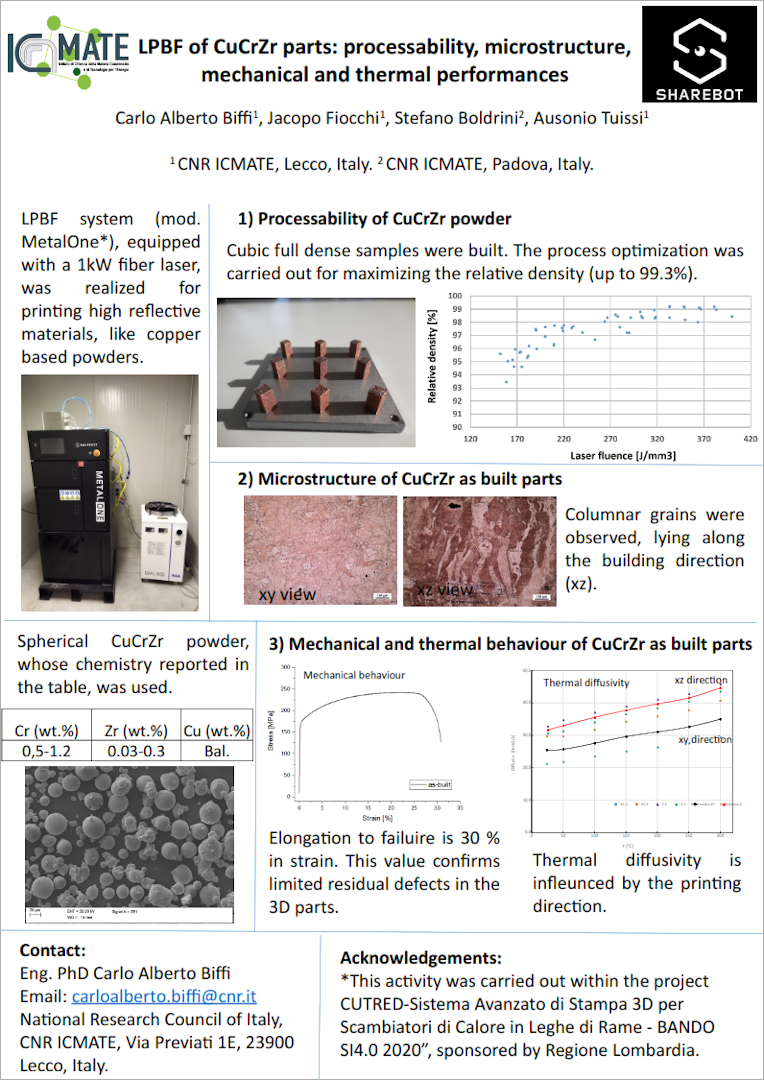

The MetalONE by Sharebot is a state-of-the-art 3D printer based on Direct Metal Laser Sintering (DMLS) technology, also known as Selective Laser Melting (SLM). Engineered for precision and adaptability, it offers exceptional reliability for metal additive manufacturing. Designed specifically for research, development, and advanced prototyping, the MetalONE is the ideal solution for professionals who demand high-performance metal parts with uncompromising quality.

Configuration Options

Customize your system for performance and application:

- Laser Power: 300W, 500W or 1000W

- Build Area: 65 x 65 mm or 100 x 100 mm

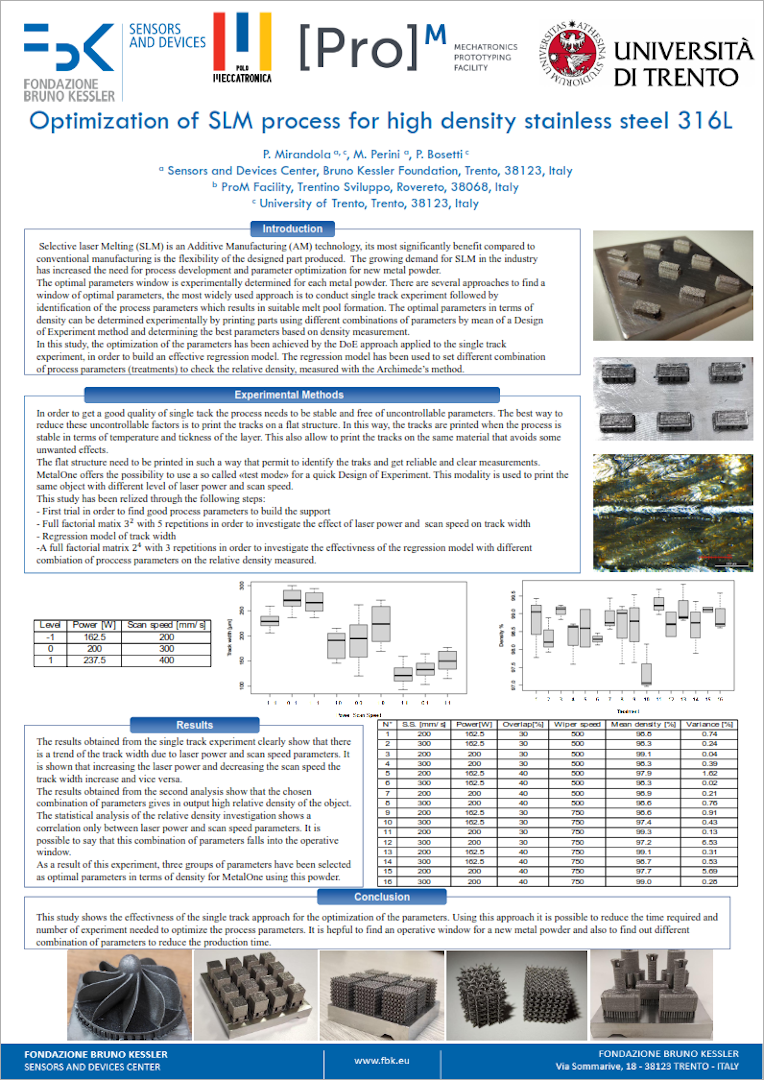

- Micro-Printing: The 65 x 65 mm area is reducible to a diameter 10 mm cylinder for testing new materials.

Flexible Configuration

The printer is engineered for versatility, offering flexible laser and build area configurations to meet diverse needs. You can select your optimal performance level from three powerful fiber laser options (300W, 500W, or 1000W), all designed for efficiency, even with highly reflective metal powders.

Choose between two build platforms: 65 x 65 mm or 100 x 100 mm. For the smallest, most accurate parts, the 65 x 65 mm area can be further reduced to a diameter 10 mm cylinder using a dedicated reducer.

Why Choose MetalONE?

The MetalONE is more than just a 3D printer; it’s a comprehensive platform for metal additive manufacturing, designed to meet the evolving needs of research, development, and production. Whether you are creating complex prototypes or custom alloys, MetalONE provides the tools and flexibility you need to succeed.

Key features

Laser: 1064nm fiber laser available in 300, 500 or 1kW version

Build area: 65x65mm or 100x100mm

Galvanometer with f-Theta lens

Open parameters

Gcode for laser movements

Class 1 laser BS EN 60825-1:2014 + A11:2021

Custom Integrations

Since MetalONE is fully developed in-house—both hardware and software—we offer seamless integration of custom tools, laser sources, or additional equipment to meet the specific needs of your research or production environment.

Read the history of our build area reduction kit.

Contact us to discuss your custom project.